We develop your business applications according to your needs and offer all associated services

Objectis offers a wide range of industrial IT services, helping its customers to automate, modernize products or improve management tools.

Services offered by Objectis

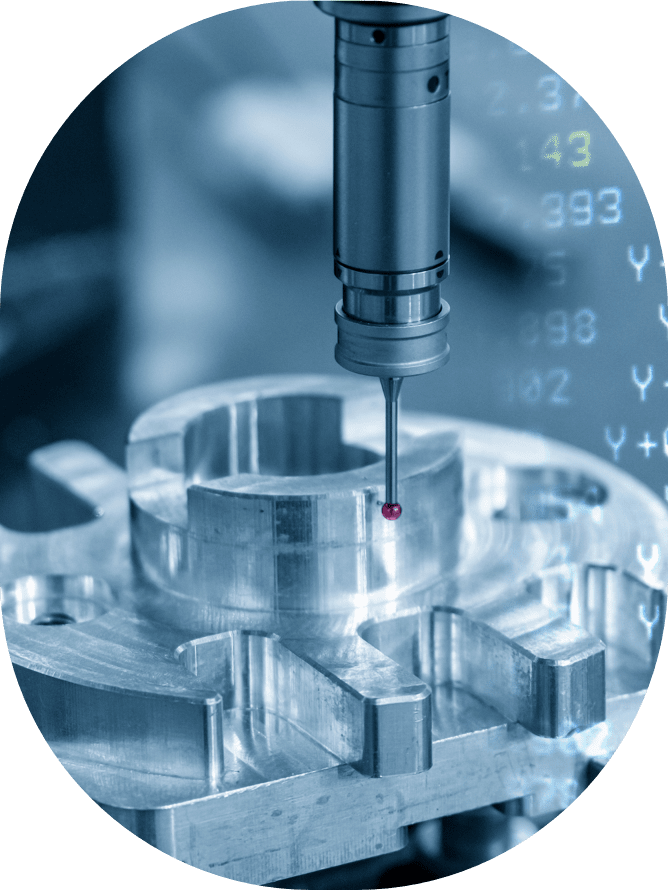

Software design and development

Professional software tailored to your specific needs.

Networking heterogeneous equipment

Consulting and API development for seamless networking of your technological tools.

Technology and Service Support

Advice and support for your technical and development teams.

Artificial intelligence tools

AI algorithms for automatic analysis of physical data and measurements.

Custom software development

Objectis, with its teams of experts, designs and develops complete, professional-quality software solutions to meet all your needs, from high-level user interface functions to real-time control on a wide range of control systems (CNC, PLC, robots, vision and embedded systems), including the integration of measurement and communication functions (Web, ERP). This service includes :

- Analysis, structuring and UML formatting of business knowledge and validation of the functional scope of a new customer-specific application framework.

- Complete software development for a customer-specific application.

- Retrofitting old software or automation systems.

Drawing on the numerous software developments carried out by our teams for our customers over the last 15 years, and grouped together in a single software platform, we are now able to rapidly develop turnkey solutions. Our Concept.Convergence platform comes in the form of an SDK, enabling users to guarantee bug-free, efficient and, above all, faster development of industrial software.

This set of libraries constitutes a powerful technological foundation, developed by our engineers using the latest software technologies and the knowledge of specialists with up to 25 years of professional experience in the field. Concept.Convergence is the synthesis of a unique know-how and expertise consolidated and demonstrated over the course of the projects we’ve worked on over the last 15 years.

The added value of Convergence

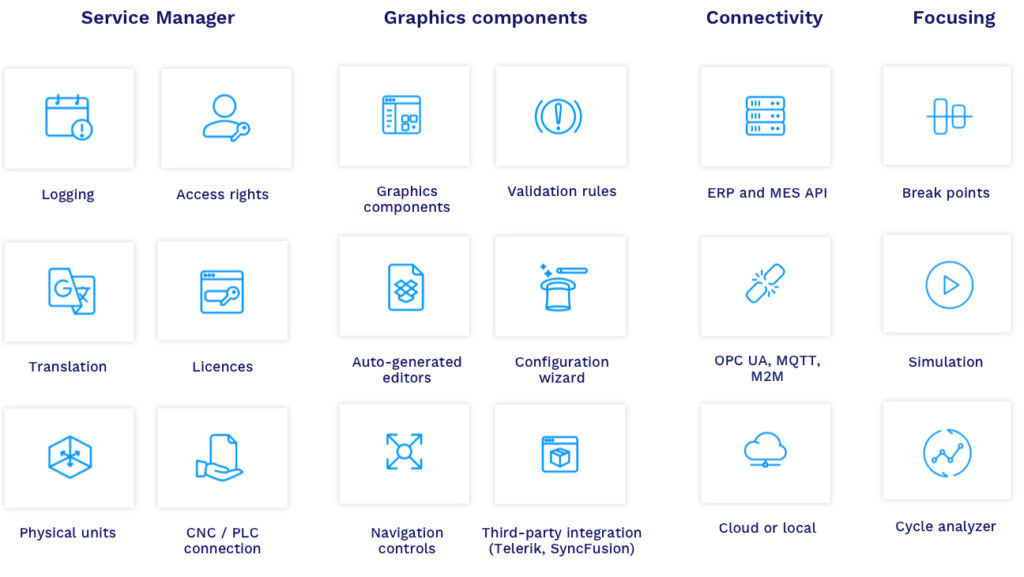

- Boosted by cutting-edge technologies

Convergence takes advantage of the capabilities of the Microsoft.Net framework and WPF and Blazor technologies to build ultra-efficient, stylized human-machine and Web interfaces. The platform is written entirely in C#. It takes advantage of the most advanced language features for outstanding efficiency, flexibility and reliability. - Communication

To meet the interconnectivity needs of Industry 4.0, the platform natively supports several secure, high-performance, open communication protocols, typically reaching a performance of 200 µs for a TCP/UDP exchange on a local network. Convergence also makes it natural and easy to use many of the industrial protocols on the market, such as OPC-UA. - Auto-generated pages and editors

The numerous input and configuration pages of an application can now be generated completely automatically by Convergence, without writing a single code line. By drastically reducing the volume of code to be written, this approach saves considerable effort, while guaranteeing a high level of logical and visual consistency. It also greatly facilitates the maintenance and evolution of applications over the long term. - UI & UX

Efficient for creating highly customizable HMIs, Concept.Convergence enables easy internationalization of applications, provides user management and traceability, offers multiple ready-to-use views, underlines your company’s image thanks to style and branding customization possibilities, and supports your users through intuitiveness and context-sensitive help. - Easy to configure

Concept.Convergence naturally handles highly configurable applications. With just a few clicks, users can adapt the application to their needs. With ready-to-use components, robotic integration, machine range declination, data and position persistence, and automatic HMI adaptation to the addition of a new function, are all done interactively.

Networking heterogeneous equipment

Networking the existing heterogeneous equipment aims to unify control and/or link your tools and machines to a coherent management system. This service is accompanied by the implementation of machine-specific “IT connectors” and data aggregation and processing tools.

We also offer the development of APIs to connect existing or future MES or ERP systems, as well as the analysis and development of specific functionalities not covered by systems already installed on the customer’s premises. This approach enables the rapid flow of digital information to facilitate the management of production operations, while making them traceable, measurable, predictable and ultimately more efficient.

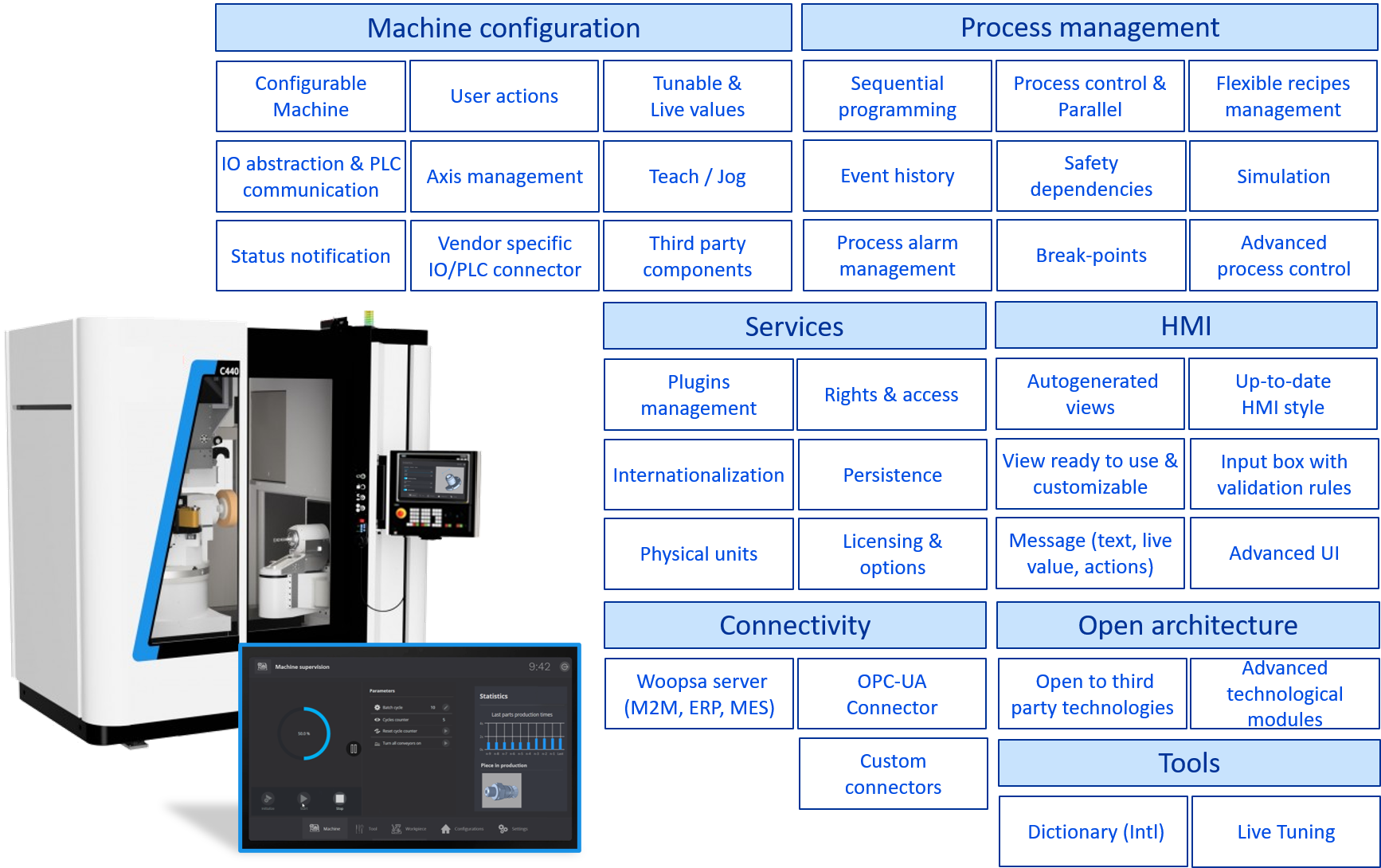

Intelligent modularity

The heart of CONVERGENCE is made up of over 70 ready-to-use functional bricks, which can be selected and combined according to the needs of the customer’s application.

What’s more, the overall structure can be extended by the addition of client-specific plugins, or new standard bricks developed by Objectis and made available to all its partners. Concept Convergence’s plug-in approach guarantees the smooth scalability and longevity of your applications.

Non-exhaustive extract of the CONVERGENCE software bricks available.

Technology and service support

Technology and service support means making Objectis experts available to advise or even temporarily reinforce our customers’ IT specialists.

This type of service can be mobilized by means of a “capacity reservation” to be honored over a mutually agreed period at the beginning of the project.

Artificial intelligence tools

Objectis has the tools to rapidly implement AI algorithms for the analysis of data, images and physical measurements that would be difficult to exploit using conventional approaches. Thanks to its expertise in the use of artificial intelligence algorithms and its pre-configured pipelines, Objectis can rapidly set up a trainable system that learns from experience and makes your production units capable of making autonomous decisions.

Quality analysis, automatic machine settings, optimization of operating parameters, identification of fault causes – these are just some of the applications set to revolutionize the potential of production units.